Area Of Expertise

Turn Around & Emergency Shutdown Works

Our plant maintenance team focuses on Maintenance Strategy, Planning and Management and it’s implementation to ensure efficiency, equipment integrity, facility security and safety.

We focus on safety and reliability in plant services, executing critical maintenance jobs with the ability to mobilize required resources who can handle Critical Materials with high Quality services

Focus On:

- Heat Exchanger Maintenance (Re-tubing, Tube to tube sheet joint repairs, Internals replacements, shell repair etc.)

- Maintenance of HP Steam Boilers, Waste Heat Boilers, Fin Fans critical materials) Process Equipment Repair Works ( Internal Build Up, Internals Replacement, Nozzle Repair/Modification Works, Shell Repair/Replacement Works etc. for equipment like Storage Tanks, Pressure Vessels, Columns, Reactors etc.)

- Weld Overlaying, Build Up, Cladding Works

- Expansion Joints Replacement

- Bolt Torqueing

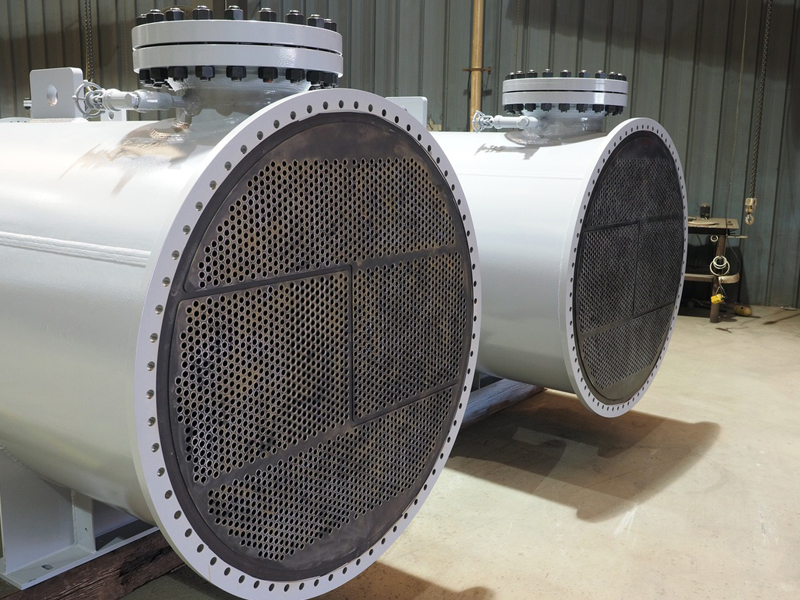

Heat transfer equipment Refurbishment

Our ability is to respond to your needs, from standard lead times to turn-key, around the clock work. We can repair heat exchangers either on-site or at our facility.

We, HTSC, perform services ranging from simple tube plugging to code weld repair and modification, to partial and complete re-tubing, complete re-build, and complete fabrication of a replacement heat exchanger. We perform both vacuum testing and

hydro-testing to determine tube to shell integrity. HTSC has the capability to take the repair works (with or without R-Stamp) for the following types both at the site or in our workshop

- Shell & Tube Heat Exchanger (Straight)

- Shell & Tube Heat Exchanger (U-Type)

- Fin Fan Coolers

- HP Steam Boilers

- Waste Heat Boilers

- Cooling Towers

Process Equipment Modification Works

Process Equipment Modification Works (with R-Stamp)

We perform process equipment repairs and modifications on-site

Types of repairs and alterations of Pressure Equipment such as Extractor column, Stripper ,Ammonia / Urea Reactor , Separator , Slagcatcher , Desalter , WOSEP drums, KO drum , Seal Drum , Scrapper Launcher etc include (but are not limited to):

Nozzle replacement, piping configuration changes, shell / head repair or replacement, cladding and weld build-up, manway repair, jacket replacement/repair etc.

All repairs will be done in accordance with the ASME R -Stamp , typically including a hydrostatic test and inspected by an independent Authorized Inspector (AI).